The Process

Archaeological objects recovered from marine environments contain large amounts of chlorides and soluble salts as a result of long-term exposure to seawater. These compounds pose significant risk of corrosion. In order to prevent corrosion and other types of damage to artefacts recovered from the sea, salts must be removed through treatment and desalination.

As a preparatory measure, all objects are cleaned from dirt and calcareous deposits. Hard and course sediments are removed mechanically or by special tools, while soft sediments can be treated by brush. Enzymes are used when treating organic compounds and the pH values of the items and other indicators are measured to ensure that conservation does not pose additional harm. For cargo pieces where there is significant risk of damage, soluble synthetic resins may be applied to minimize loss of paint, detail or other decorative surfaces.

Subsequent to surface cleaning, non-metal objects, such as ceramics, stone, glass and wood, are desalinized by soaking them in baths of water purified by reverse-osmosis. Throughout this process, scientists measure and test salinity levels of the treatment baths to prevent growth of micro-organisms and ensure that additional stress is not exerted on artefacts. Over time, the salts leave the objects and move out into the desalination baths, leaving the artefacts as free of salts as possible. When complete, the artefacts are places on drying racks and inspected.

For metals, such as bronze, silver and gold, corrosive materials must be removed mechanically by scalpel, sandblasting or micro-grinding, or alternatively through chemical treatment. These objects are also desalinated, although through an electrochemical process that is optimized for medal surfaces. Subsequently, the artefacts are treated to prevent further environmental damage, often with chemical treatments.

The following article by Andreas Rettel describes in detail the conservation methods.

Andreas Rettel

The Concept of the Conservation of Seawater Finds

The concept of the conservation and

restoration of a vast amount of found objects is a great task for private and

state-run institutions. It would be better for various excavation finds in the

world to remain hidden, because then they would not be exposed to new and

variable environmental conditions, which are the cause of the continuing

deterioration of the objects. This is particularly true for seawater finds.

Against this background and

because of the sense of responsibility for the salvaged cultural assets of the

interesting cargo from the

This chapter explains the

framework of the measures. In some cases that can be regarded as representative

for groups of wares, I will go into the treatment of individual objects in more

detail. The amount of different objects does not permit a detailed listing of

their particular conservation needs.

I. Conservation and Restoration of Ceramics

a. Conservation

Seawater finds present a

particular difficulty regarding conservation: Depending on their material,

composition and the period they have been on the seabed, these objects have

deposits and have been penetrated by substances typical of the medium seawater

or have formed chemical compounds and are corroded.

Ceramic seawater finds have

become saturated with salts without them entering into a chemical reaction with

the components of the ceramics. They can, therefore, be removed in pure water.

These salts are ineffective as long as the objects are on the seabed or stored

in ideal storage conditions. If the objects dry out untreated or if they are

exposed to changing storage conditions, the salts that have penetrated them are

activated to move in the course of time. They accumulate beneath the denser

outer layers where they can crystallize. During this process, pressure develops

that can cause the denser outer layers and glazes, respectively, to exfoliate

or be damaged.

To avoid this, a concept of

conservation has been developed that ensures the controlled desalination of the

ceramics.

The kind and number of

ceramics from the

For ceramics of the same

manufacture – form, glaze, thickness of the material, kiln – the

same water and salt absorption can be presupposed. The desalination process,

therefore, is the same for these ceramics, which made it possible to construct

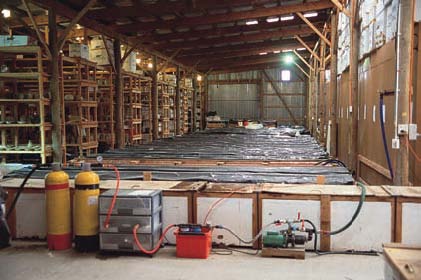

large basins correspondingly. The basins were arranged in rows accessible from

the side to fill and empty them as well as to control the desalination progress

by measuring the results on the bottom in different places (fig. 3).

Preparatory measures

Most objects were cleaned

from adhering dirt and calcareous deposits before they were put in the

desalination process (fig. 1). This ensures a smooth running of the facilities

and possible peculiarities of the objects are recognized earlier, the speed of

the process is increased and the measurement of the desalination is simplified.

Very hard and coarse

sediments are removed mechanically with the help of micro grinding devices or,

if possible, with dental tools, e.g. scalpel. The cleaning of softer sediments

is done under running water with the help of a scalpel or a soft brush. If

there is deep organic soiling, enzymes are used.

If applying one of the

mechanical methods mentioned above would mean a risk of damaging the original

surface, the object is cleaned with appropriate chemicals. It depends on the

object which strength and type of chemical is applied, long exposure times

should generally be avoided.

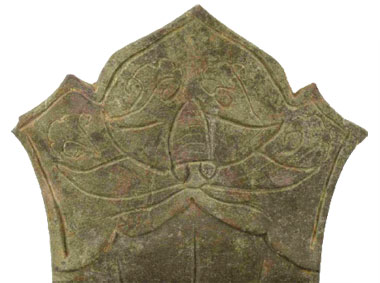

Fig. 1 Check of condition of the ceramics

(Photograph: A. Rettel).

Repeatedly, compresses that

have been soaked in chemicals are put on the ceramics that have been thoroughly

wetted with water before that treatment until the deposits are removed. After

this treatment, the ceramics are extensively soaked in water and are checked by

means of pH value.

The glazes that were used

in the cargo are more or less prone to flake off the ceramics. Soluble

synthetic resins (glue dissolved in alcohol or in acetone) are applied to the

parts at risk to stabilize the sensitive glazes on the ceramics. This is done

in an individually adjustable extensive fume extraction system constructed

especially for that purpose. The mixing ratio is chosen in such a way that the

resin penetrates the fine cracks of the glaze and consolidates it from behind

by gluing it together without harming the appearance of the glaze. Excess of

the synthetic resin on the surface is dissolved in solvents and removed. The

choice of the consolidant depends on the state of

preservation or on the stability of the objects.

The individual ceramic

objects that have been cleaned, consolidated and graded according to their

kilns and types are put into basins (fig. 3) without point of contact with one

another as far as possible. Depending on their forms, special attention is

given to the optimum way for them to be washed round, and to stability. When

the water of the basins is changed, it is important to avoid ‘air

chambers’ in order to achieve the maximum salt extraction and to keep the

objects placed in a stable way.

Desalination

The medium water used for

desalination was examined for harmful substances and classified as completely

harmless. When the desalination of the ceramics is started, the necessity can

arise to add salt to the water since stress exerted on the sherd

can lead to reactions, too. This was tested in the preliminary stages of the

desalination measures and considered not necessary.

The basins are covered with

black foil to protect their contents from soiling and incident light –

development of microorganisms. The basin system that was created according to

these requirements has the advantage that it is possible to statistically

control the groups of wares during their desalination process, which is

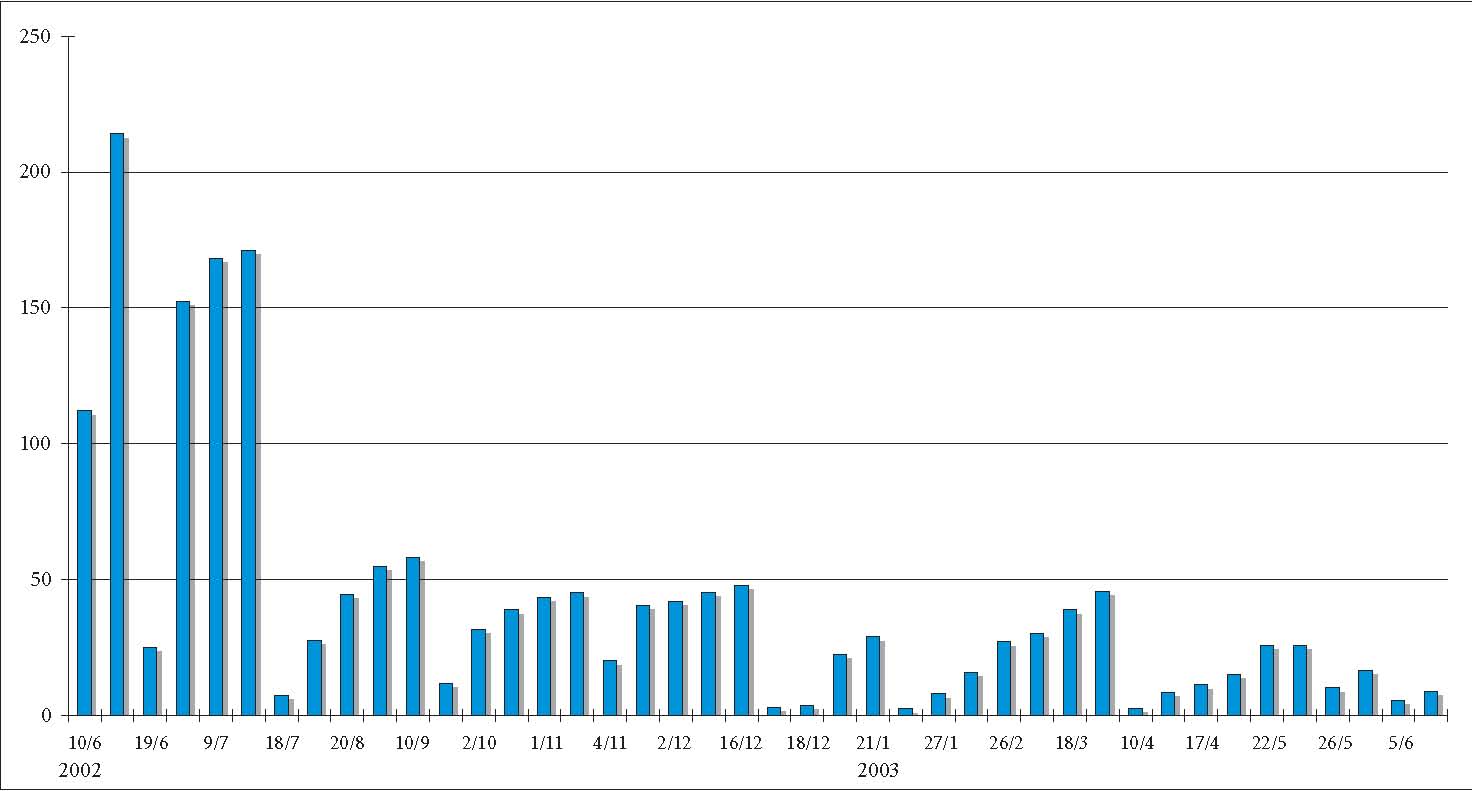

documented through regular measurements (fig. 2).

As water always endeavours

to distribute soluble substances as evenly as possible, the deposited salt is

extracted from the ceramics. At the beginning of the desalination process, this

is more evident because at unglazed spots, an easy transportation of salt in

solution is ensured.

Due to the density of the

glaze, the extraction is hindered at glazed spots, which is documented by lower

results but still continuous salt emission in the process of water changes and

readings.

Fig. 2 Example of a desalination graph.

The dissolved solid

substances in the water are measured by means of a conductivity meter, which

shows an increasing flow of current between anode and cathode (microsiemens). This measurement method by means of

conductivity meter can be applied to objects that have been cleaned from

concretions; with objects that have not been cleaned and treated, the chloride

content has to be determined directly since other minerals like calcium ions also dissolve into

the water. Due to the different forms of wares, different amounts of water are

available for the desalination of the individual object, which has to be

considered regarding the results of the measurement. The water changes are

carried out according to the documented results; it is always the same amount

of water that is used in the basins. As soon as one basin reaches the stage of

a slower rise in results, the water is pumped through a cycle comprising a

de-ionisation system (20 l/min) and a UV-light filter (fig. 3).

We use a reversible

synthetic substance for deionisation and special UV-light waves to destroy the

microorganisms that develop despite the covering foil, without having to fall

back upon chemicals which could be harmful to the objects. This process is

repeated at certain intervals until the results stagnate again. To substantiate

the statistical value, some objects from different basins are put into

individual basins with deionized water – if the

results do not change here, the desalination is regarded as completed. The

subsequent drying takes place on shelves, slowly and under plastic foil if

necessary. Then, all the ceramics are checked again regarding the state of their

glazes and they are consolidated again or any excess consolidant

is removed if need be.

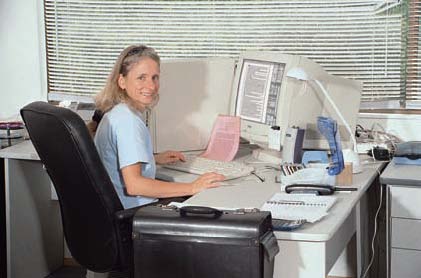

Archiving

The objects that have been

combined in groups are now individually photographed and entered encoded into

the data collection. The code includes the following information: kiln, form,

desalination graph and numbering. The conserved state of the object is recorded

in this way and it forms the starting point for a condition and treatment

report in which also all of the fol lowing treatments

and the photo of condition are entered to ensure the best transparency possible

for all of the following measures (fig. 4). Comparative studies on the part of

the archaeologists, classification according to distinguishing characteristics

as well as all restoration measures can now be entered individually.

Fig. 3 Part of the basin unit (Photograph:

A. Rettel).

Fig. 4 Entry of data (Photograph: A.

Rettel).

b. Restoration

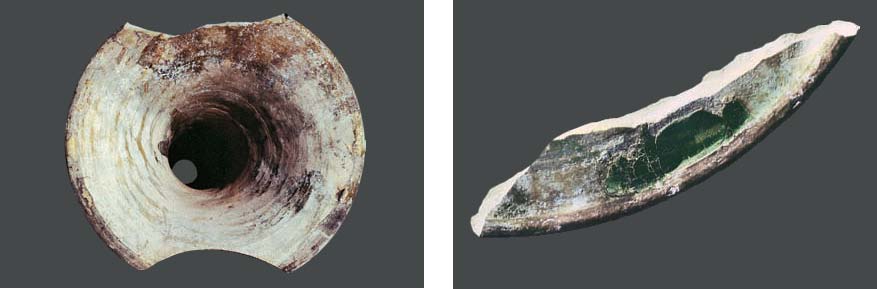

The restoration of archaeological objects is a sensitive topic; it

includes subjective points of view. When the visible texture in the broken sherd has been analysed scientifically, one person might

like to leave it in this state, another one, however, might think that an

object which has been reconstructed according to special requirements with the sherd of the original fitted in at the right spot, is the

right step towards understanding the ancient cultures better in their technical

capabilities and skilfulness, in their forms and coloration. Aims of

restoration are conservation and restoration of the original state of the

object as far as possible and justifiable. It is possible within certain limits

to restore changes or damages that have been caused to the object whose original condition can be proved

through comparable objects (cf. figs 5a–d).

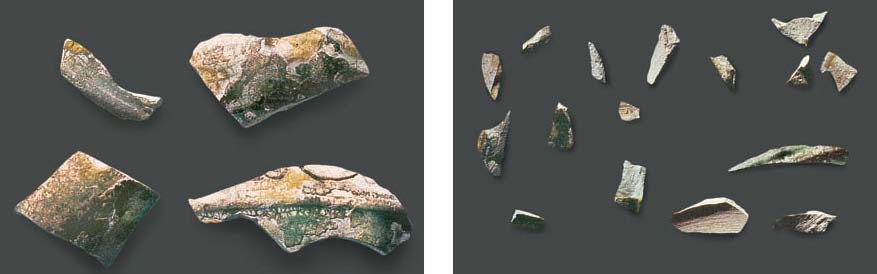

Fig. 5a, b Sherds of

the bowl no. 62, top (above) and bottom (below) view

(Photographs: A. Rettel).

Fig. 5c, d Plaster replacement of no. 62

defined through original form and comparable objects; top (above) and

bottom (below) view (Photographs: A. Rettel).

Changes to

the object as, for example, corroded glaze always remain in their respective

state. The cleaning of sticking oxides, removal of cracks, replacement of

missing parts and retouching them are done for static and aesthetic reasons.

Fills are retouched if the missing part is small. Bigger replaced parts remain

unpainted. The intervention in the original colour design of the manufacturer

seems too great in these cases. The priority is here not to change the

character of an antique object, i.e. objects are not supposed to look new but

to show their antique traces. Damaged parts are restored according to the

character of the object so that their repair becomes a harmonious part of the

object. Missing glaze on the ceramics is not filled. All materials used for

restoration are selected according to their greatest possible reversibility.

The restoration measures are documented in writing and photographs in the

condition and treatment report of the object so that all the different steps of

the process remain comprehensible.

Each one of

the objects that are to be restored is discussed beforehand with the

conservators concerning requirements and possibilities. Documentation is a very

important factor here. Only documented restoration work allows doubt-free

scientific research and allows the public to see the artistic skill of the

ancient manufacturer.

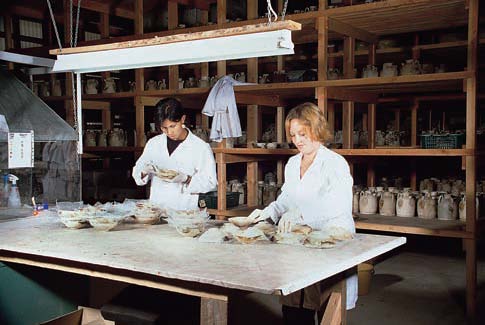

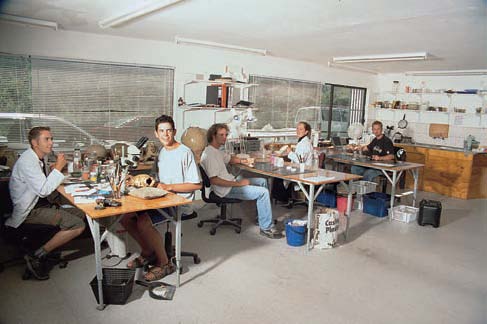

Fig. 6 Ceramic

restoration laboratory (Photograph: A. Rettel).

General description of the completed restoration

measures

Broken pieces that belong

together are glued together with reversible glue in such a way that edges

cannot be felt. Chipped off pieces are filled – with plaster or an

air-drying modelling clay depending on the size of the missing part – and

then retouched. If mechanical impact has caused cracks in the ceramics, stress

that came into existence through the manufacturing process is released, which

causes the fracture edges to distort. These cracks are drawn together and glued

if the stress inherent in the ceramics makes this possible.

Missing pieces whose

original form is defined through comparable objects are filled with plaster

that is tailored to the exact form of the object. For this purpose, a template

is made of the original. The ceramic object is soaked well before the missing

part is replaced so that it does not draw water from the plaster fill. The

material plaster is used because it does not cause damage to the original. The

transition to the original surface can be aligned well without damaging it.

When the plaster is brought into its form, plaster dust develops that could

stick to the fine pores and cracks of the glaze or to the unglazed spots. To

avoid this, the adjacent surfaces are treated with a reversible protective film

(Revultex, B72) that seals the surface. After

completion, it is removed again. Fine dirt or plaster traces that exist on the

surface in spite of the precautions are removed by applying a latex solution,

which is followed by wiping it off during the curing process.

Fig. 7a Hu ewer

no. 75: Top view of fracture at trumpet-shaped foot towards the middle ring;

remnants of the middle ring, glued onto the foot by glaze firing (Photograph:

A. Rettel).

Fig. 7b Hu ewer

no. 75: Top view of the fracture edge of the middle ring around vessel body,

originally very thin wall, with respect to weight and size of the object,

stabilized on the inside with synthetic gauze (Photograph: A. Rettel).

Figs 7c, d Fragments

of the middle ring of hu ewer no. 75 (Photographs: A.

Rettel).

Fig. 7e Hu ewer

no. 75: Bottom view of foot, one sherd broken off,

one piece missing (Photograph: A. Rettel).

Fig. 7f Original

sherd of hu ewer no. 75

(Photograph: A. Rettel).

Fig. 7g Hu ewer no. 75: Fragments of the middle ring put together

with foot and vessel body, stabilized from the inside, missing pieces and

chipped off pieces filled with plaster and an air drying paste (Photograph: A.

Rettel).

Fig. 7h

Retouched fills of hu ewer no. 75 (cf. fig. 7g) (Photograph:

A. Rettel).

Missing handles, loops,

feet and the like are copied from an identical part of the same object or other

comparable objects by means of moulding material, they

are fitted in the exact place, filled with plaster and touched up. Gaps and small

chipped off pieces are filled with an air-drying paste.

Parts like these are

retouched with oil colours (according to their glazed surface and colour) and

if they have a glossy original glaze, they are polished. The last step is to

apply a very small amount of protective acid-free museum wax with a piece of

lint free cloth – and slightly polish it. Every single object is finally

checked and the stability of its condition, i.e. the colour of the filled

parts, is controlled for a while. Every fill that has been made is documented

and comprehensible as well as reversible at any time (cf. figs 7a–k).

Figs 7i, j Missing

piece at foot of hu ewer no. 75 filled with plaster

(above); retouched fill (below) (Photographs: A. Rettel)

Fig. 7k Hu ewer

no. 75, desalinated, glaze stabilized, restored (10.43 l. volume) (Photograph

courtesy Seabed Explorations).

II. Conservation and Restoration of Metal Objects

As with land excavations,

corrosion of antique metals found on the seabed depends on environmental

influences: for example aerobic or anaerobic area, buried deep down in the

sand, rocky surf, composition of gas mixture of the water, vicinity of other

metals, salts deposited in the corroded parts, as well as the reaction of the

respective metals to the respective factor, might all play a part in the

various forms of corrosion. When corroded metals are salvaged, they have to be

kept moist and be put into nitrogen to keep away oxygen and any further

corrosion that is connected with it.

a. Bronze

The bronze objects from the

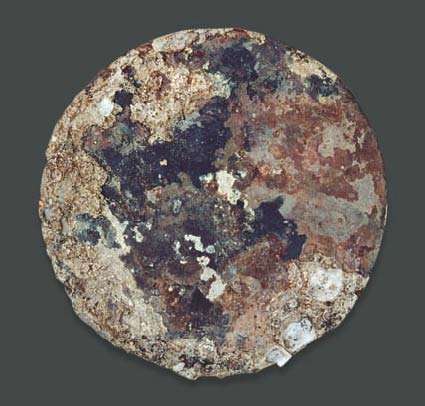

Fig. 8a, b Mirror no. 24: Condition at time of

discovery; décor side (top) and mirror side (bottom)

(Photographs: A. Rettel).

Various mirrors with

different designs have been salvaged (see pp. 194–223). Chinese mirrors

were cast in a so-called mirror-bronze which is very close to silver in colour

and which is polished to brilliance on the mirror side. Due to the long period

of time the objects had been on the seabed, different types of corrosion had to

be removed from the surface under the sediments. Dif ferent

states of conservation required different procedures. On well-conserved, stable

surfaces, the corrosion could be removed carefully from the original surface

with a trihedron scraper or scalpel and micro fine

grinder, respectively. The colour of the metallic surface which reappeared had

changed to blackish in the course of time as the objects had been lying in the

seawater, next to lead, for a long period (cf. figs 8a–c).

Especially in the case of

badly-conserved surfaces below corrosion and sediments, it is better to get a

clear idea of the surface that has to be cleaned in order to be able to take

better care with depictions and details of the work and to recognize the degree

of the different impacts of corrosion and conditions there. This is done by

taking an X-ray, whose kV strength and duration of radiation are regulated

depending on the thickness of the material and its condition. At the light box,

one can recognize the composition of the picture of light and dark parts in

gradually changing shades. The lighter ones are those that could not or less

well be penetrated by the X-rays; the dark ones are the thinner or corroded

parts (cf. fig. 10 and below p. 137, fig. 1; p. 139, fig. 4; p. 141, fig. 7).

Fig. 8c Mirror no. 24: Décor side,

after completion of conservation and restoration measures (Photograph courtesy

of Seabed Explorations).

Restoration of bronze – one example

In the case of the mirror

no. 22, the exact depiction of the inscription was required although the

surface was in a very bad condition (figs 9a, b). Using the information

provided by the X-ray (fig. 10), the characters and depictions could be cleaned

mechanically under the microscope – deposits were removed by means of

scalpel, micro grinding devices or micro sandblaster (using soft material).

During this process, the corroded, unstable and damaged surface was

consolidated reversibly whenever it was necessary. The mirror halves were

soaked in distilled water and controlled.

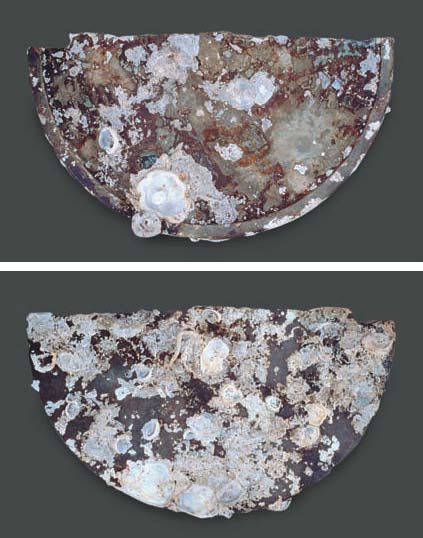

Fig. 9a, b Condition of one half of the mirror

no. 22 at time of discovery; décor side (above) and mirror side (below)

(Photographs: A. Rettel).

After cleaning the surface

and the fracture edges (figs 9c, d), we desalinated in accordance with the

electrochemical (e m f ) series of metals. Remaining

salts in the bronze are activated to corrode to aluminium foil through contact.

Other bronze objects with a more stable surface were desalinated in accordance

with the Thouvenin method. After the desalination,

the object is rinsed well in distilled water and dried under an infrared lamp.

To stabilize the surface, a treatment with benzotriazole

was carried out.

Corrosion points in the

fracture edges of both mirror fragments are found out and removed under the

microscope with the help of occlusion

Fig. 9c, d Intermediate photograph after

removal of deposits and corrosion from the surface of one half of the mirror

no. 22 using the X-ray; décor side (above) and mirror side (below)

(Photographs: A. Rettel).

paper to allow the fragments to be put

together again with optimum precision. Both halves are put together in their

original alignment and they are fixed firmly. As an adhesive, a special twocomponent epoxy resin is applied with the help of dental

instruments in such a way that it can spread between the fracture

edges without excess. This does not yet produce a smooth transition to the

original surface after it has hardened. The smooth transition is produced by

applying identical synthetic material, thickened with talcum powder and tinted

in the various shades of the original surface and after it has hardened, it is

worked to an even surface level. The missing piece is also filled smoothly with

tinted synthetic material. The cleaned surface was matt due to corrosion and

was treated with calcium carbonate. A thin application of paraloid

B72 to which some BTA is admixed, as well as the final application of a special

wax coating, constitute the termination of the process

(fig. 9e).

Fig. 9e Joined mirror halves (no. 22) after completion of conservation and

restoration measures (Photograph courtesy Seabed Explorations).

The steps of the procedure

are documented by photograph of condition, X-ray, intermediate and final

photographs as well as treatment entries in the condition and treatment report.

The filling measures can also be identified as such at any time by means of

X-ray pictures.

Fig.

10 X-ray of the

mirror no. 22 (Photograph courtesy Seabed Explorations).

b. Silver

The silver objects of the cargo

were in various states of conservation: all were covered by black corrosion

layers and sediment deposits. There were complete objects and objects broken

into pieces or corroded objects with missing pieces (figs 11a, b). The

different states of conservation can be explained by the fact that

- they were in seawater for a

long time

- some objects were stored safely

inside other objects and, in this way, protected

- the metallic conserved silver

changed its structure through intercrystalline

corrosion and is susceptible to breaking when deformed or stretched

- direct vicinity and influence of

other metals, in our case lead and iron.

The corrosion layer of the

silver ingots could – in parts - be removed well mechanically from the

surface (fig. 11c, d).

Small ingots were in such

an advanced state of corrosion that one side could be cut open with a dental

diamond cutting tool and removed with an instrument and then, the silver piece

could be taken out. Apart from the silver ingots, all the silver wares are partially

gilded and decorated.

Bottom and lid of all of

the boxes were firmly corroded together. The calcareous deposits were removed

mechanically with a scalpel or chemically from the soaked boxes and the boxes

were rinsed well repeatedly.

Fig. 11a Example of the fragments of a

partially gilded silver plate; photo of condition (Photograph: A. Rettel).

Fig. 11b Example of the fragments of a

partially gilded silver plate; X-ray of central area (Photograph courtesy of

Seabed Explorations)

Diluted hypochloric

acid (5–10%) was used, and the objects were rinsed well afterwards. The

corrosion layers came into existence through the respective circumstances of

storage and influences and, in its corrosion process, the silver diffused

through the gilding and formed very strong and solid layers of a conglomerate

of silver sulphide, chloride, bromide and calcareous concretions (figs

12a–i).

|

|

|

Left: Fig. 11c, d Silver ingots no. 11a, b: above before

restoration (Photograph: A. Rettel); below after completion of

conservation and restoration measures (Photograph courtesy of Seabed

Explorations).

Right: Figs

12a–c Silver box no. 18 after removal of calcifications; side (above),top

(centre) and bottom (below) view (Photographs: A. Rettel).

Figs 12d–f Silver box no. 15 after removal of

calcifications; side (above), top (centre) and bottom (below)

view (Photographs: A. Rettel).

Fig. 12g–i

Silver box no. 12 after removal of calcifications; side (above), top (centre)

and bottom (below) view (Photographs: A. Rettel).

As the silver corrosion

products corroded out of the material of the boxes, the silver structure on and

beneath the surface changed. Concerning the completely intact boxes, the

structure of the inside was conserved better. Only thin corrosion layers had to

be removed. The gilded parts could partly be recognized because of their

thinner corrosion layer compared to the pure silver surfaces because the gold

layers hindered the silver’s corrosion. The removal of deposits from the

original surfaces of the gilded silver objects was carried out either under the

microscope, mechanically with scalpel, wooden or acrylic glass pins, or –

for coarser deposits – micro grinding device (diamond). Some areas of the

corroded surface were treated by chemical or electrolytic reduction.

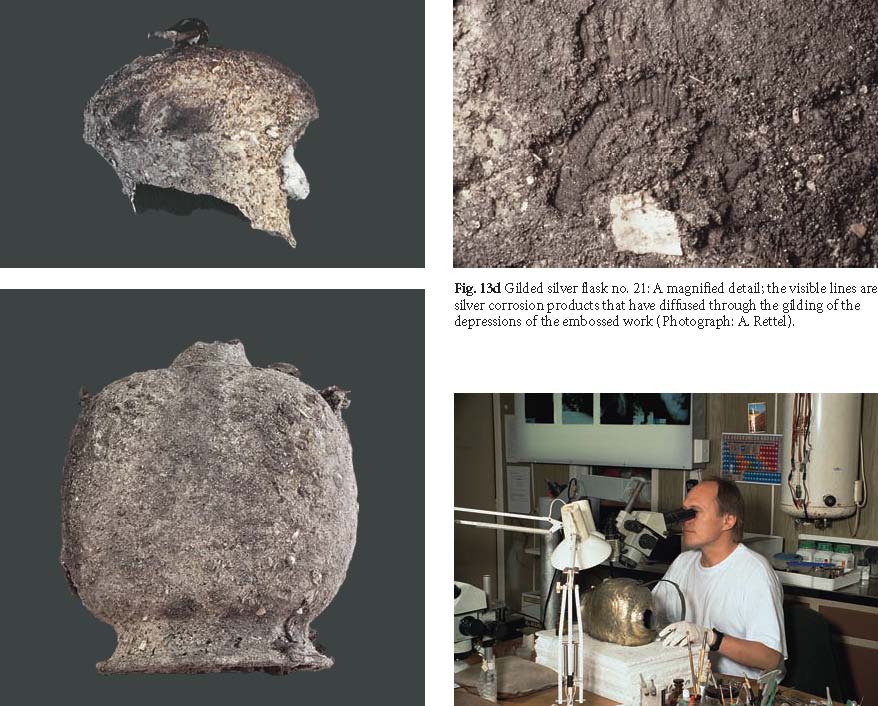

Fig. 13a Gilded

silver flask no. 21: Neck and corroded lid broken off; cleaning of lid, neck

and shoulder started (Photograph: A. Rettel).

A different corrosion could

be seen on the outside of the completely gilded flask no. 21. The neck of the

flask with its corroded lid was broken off, due to the intercrystalline

corrosion of the material. The neck does not sit accurately on the fracture

point due to its slight deformation at the time of breaking (figs 13a–c).

Beneath the layers of

calcareous deposits, there was the black silver corrosion I have already

mentioned, which showed various structures: chipping off, very strong, softer,

or firmly adherent. The corrosion had partly diffused through the gilding in

such a way that defects had formed underneath and, due to this circum stance,

in these areas, the plating was only held by the corrosion from the outside; in

places, it had separated from the corroded ground. These spots had to be

consolidated from behind so that they would not come off during the cleaning.

The corrosion had grown extensively where the gilding was missing or at spots

where the gilding was thinner, for example in the area of the depressions of

the embossed work (figs 13d).

Fig. 13b, c Gilded

silver flask no. 21: Condition at time of discovery; broken off neck with lid (above)

and front view (below) (Photographs: A. Rettel).

Fig.

14 Restoration of

silver flask no. 21 under the microscope (Photograph courtesy Seabed

Explorations).

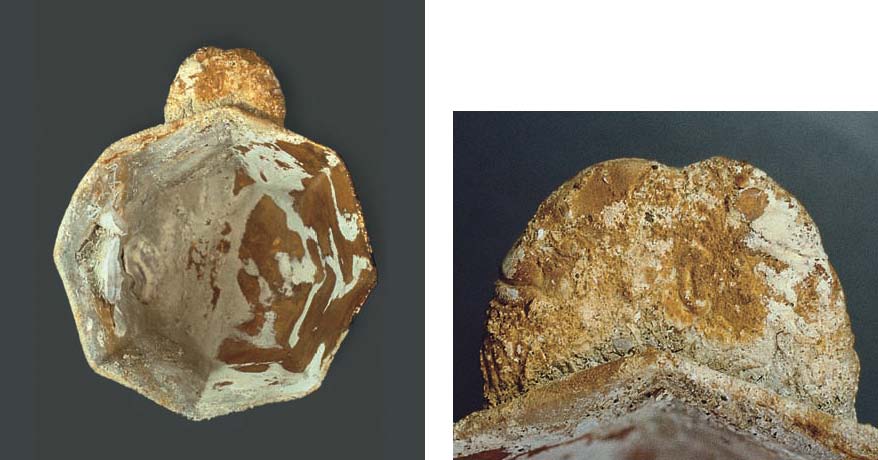

c. Gold

The gold objects were also

covered by hard layers of sediment. After removal of these layers, the gold

surface partly appeared. With high-quality gold, corrosion is only possible at

soldered points. In our case, there were reddish brown thin corrosion products,

which lay extremely firmly and hard on the surface. They could be removed with

the help of a mixture of a solution of EDTA and other chemicals to remove iron

oxide. The rest was removed under the microscope with soft wooden or acrylic

glass pins while meticulously taking care not to leave any traces of the

exposure on the soft gold surfaces. No copper corrosion could be seen at the

soldering points of the objects, which indicates the use of a high quality gold

solder.

Fig. 15a Gold cup no. 1, condition at time

of discovery (Photograph: A. Rettel)

Fig. 15b Figure on gold cup no.1 before

removal of deposits (Photograph: A. Rettel).

Gold cup no. 1 (figs 15a–d)

No corrosion was found

behind the soldered figures that are slightly raised from the surface of the

cup, even under strong magnification. It is a high-quality gold solder which

made the producer turn to a special technique because of the high melting range

temperature and the multitude of pieces that had to be soldered in one single

operation: A mould was made in which the cup with the dressed figures was

clamped. The gold solder had already been put between the cup and the figures

so that merely soldering points were produced behind the figures instead of

soldering them extensively. The cup was heated until the parts were joined

together. At the same time, pressure was exerted on the cup, as proof you can

see the bulges of the silhouettes of the figures on the inner wall. The base

and handle of the cup are soldered, too.

Fig. 15c Gold cup no. 1, condition at time

of discovery; top view (Photograph: A. Rettel).

Fig. 15d Soldered handle thumb plate, depiction

of two bearded faces; condition at time of discovery (Photograph: A. Rettel).

III. Conservation of Organic Materials

a. Wood

Various wooden objects as

well as parts of the vessel were salvaged (cf. nos

331–335). Water reduces the elasticity of the cellulose structure of wood

in the course of time. If such wood dries up, it shrinks and cracks –

different sorts of wood react slightly differently. The wooden objects,

therefore, were immersed in PEG (water-soluble) for a period of three years.

This wax penetrates the wet wood and, while drying, consolidates the cell

walls, which retain their shape.

Afterwards, the objects

were slowly dried under plastic foil. This process was controlled by measuring

the objects’ weight. When the weight remained the same, the drying

process was finished.

Lacquered wood

A wooden dish (no. 312),

lacquered red on the inside, black on the outside was immersed in PEG, too.

Flaking off lacquer was consolidated with wax.

b. Ivory

The drilled ivory knobs

(no. 321a–d) and the ivory rings (no. 320a,b)

were desalinated in distilled water, which was subsequently replaced with a

water-displacing solvent. Then the objects were immersed in the same kind of

solvent, in which B72 was dissolved in a steadily in creasing concentration.

The subsequent drying was controlled by measuring the objects’ weight.

Small missing parts were filled with microcrystalline wax. Final

treatment with a thin layer of acid-free museum wax.

c. Rope

Immersed

in PEG.

d. Resin (no. 322)

Soaked in

distilled water, stable condition.

e. Solids for ink production

The fragments were

consolidated while wet. A small amount of fragments and crumbs was slowly dried

without treatment for analysis.